Our Pre Engineered Building System system is unmatched in its speed and price. Buildings to suit specific desires, are designed, engineered, manufactured and shipped in less than 7 weeks and at a cost that is as low as 25% of the cost of conventional steel buildings (when compared to speed of occupancy and space usability).

From planning to occupancy, nothing matches Riddhima Building System Pre Engineered Building System in terms of versatility, flexibility and total value-engineering. The pre-engineered building system is, no doubt, one in all the quickest growing building systems within the world. the benefits that it offers charm to all or any parties concerned within the project. After all, UN agency will resist a building system that gives speed, quality and value.

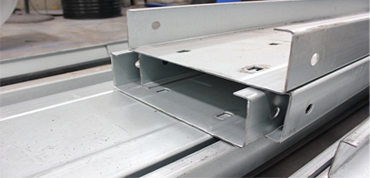

RBS is the pinpoint brand of high grade quality of Pre Engineered Building. We have a large range of PEB systems which includes a standard rigid frame, tapered frame, clear span, etc. We area unit producing PEB Buildings by exploitation the most effective quality material and spare parts which is been sourced from the exclusive vendors within the market. We area unit producing these Pre built building frames as per the customer’s demand whether or not or not it's the steel styles or the other metal solid demand is there. There area unit varied dimensions and segments within which these pre built buildings area unit framed. We area unit producing these frames with the team, of trained and skilled civil engineers UN agency area unit qualified enough to create and style these frames for a specific comes.

Advantages

Pre Engineered Buildings requires the reduced time for construction purposes.

To manufacture the economical buildings, pre engineered buildings is the best suitable option.

These pre engineered are made flexible for the expansion purpose if in case it is required in the future.

We are manufacturing these peb structures with the larger spans or in whatever dimensions which are prescribed by the customer or client.

These are made with the superior and strong quality version.

We are manufacturing the peb structures which requires the least maintenance and are cost effective.

These are made in the energy efficient roofing and wall system. These frames involve the structural versatility as per its applications and usages.

Applications

Pre Engineered Building are suitable to be designed for the various purposes. It may be Warehouses, Cold Storage, Super markets, Aircraft Hangers, Production sites, Sports club and various other building usages.

These Pre Engineered Buildings can be delivered to the clients within the maximum time of 2 months. We are the recognized brand of delivering the best quality of PEB structures in the superior grade quality as per the industry standards and international norms of certifications.

We also provide our services in Gurgaon, Haryana, Delhi, Bihar.